ASCS 2695 AusSpill Association standard for Spill Response Kits

Download a PDF copy of this document here

This standard was prepared and approved by the members of AusSpill Association, A Voice for the Australian Spill Control Industry.

This standard is not legally binding. It has been approved by AusSpill and applies only to Auspill’s members. See our FAQs page for information on why the standard was developed.

This standard was published on 27th November, 2018

AusSpill Association members at time of writing:

3m

Absorb Environmental

Coxen Cleaning Chemicals

Ecospill

Envirosmart

Matthews Safety Products

Paramount Safety Products

Prenco Environmental Spill Control

Spill Station Australia

Associate Member:

Haydn Rossback

PREFACE

This standard has been developed by members of the AusSpill Association. The objective of this document is to promote the safety of people and prevent damage to property and the environment through the use of standardised spill response kits.

The terms ‘normative’ and ‘informative’ have been used in this industry standard to define the application of the appendix to which they apply. A ‘normative’ appendix is an integral part of a standard. An ‘informative’ appendix is only for information and guidance.

1 SCOPE

This standard provides compliance requirements for spill response kits.

Aspects of spill response kit compliance referred to in this standard are:

- Sorbent capacity testing

- Appearance

- Colour coding

- Descriptors

- Labelling

- Mark of Recognition

- Maintenance

2 Application

This standard applies to all spill kits manufactured, assembled, sold and used in Australia, by AusSpill Association members.

Spill response kits packed in mobile bins shall comply with all sections.

Spill response kits packed in other spill response kit containers shall comply with section 2, 4 and 5.1 (a), (b), (c)

3 DEFINITIONS

AusSpill Association

Australian Spill Control Industry Association

3.1 May

Indicates the existence of an option

3.2 Mobile Bin

Plastic bin with lid and two (2) wheels. Generally 120L, 140L or 240L. Commonly use as kerbside waste receptacle

3.3 Other spill response kit containers

Spill response kit containers other than a mobile bin

3.4 Shall

Indicates a mandatory requirement of the standard

3.5 Should

Indicates a recommendation

3.6 Sorbent capacity

The maximum sorbent capacity of the spill response kit as determined by testing undertaken by an independent laboratory approved by AusSpill Association.

3.7 Spill response kit

An assembly of products used when responding to a spill, leak or other escape of liquid. A spill response kit should consist of some or all of absorbent pads, booms, loose absorbent, personal protection equipment and contaminated waste bags that are packed in a readily identifiable weather resistant container.

3.8 Spill response kit container

Any primary device in which a spill response kit is contained

SECTION 4 SORBENT CAPACITY TESTING

4.1 Scope of Section

This section specifies the test method used in order to accurately determine the sorbent capacity of the spill response kit.

4.2 Determining maximum sorbent capacity

In order to determine the combined maximum sorbent capacity of the sorbent materials assembled in a spill response kit, a sample of each type of sorbent component shall be tested individually by an AusSpill approved laboratory against British Standard test method BS7959-1, “Materials used for the control of liquid spillages, Part 1: Determination of sorbency.” The maximum sorbent capacity of the spill kit can not exceed the sum of the capacity of the sorbents in the kit, derived from the test data of each sample.

Original sorbency test results issued by the AusSpill approved laboratory shall be made available to the AusSpill secretary for verification in the event that spill kit sorbency claims are contested by an AusSpill member.

SECTION 5 SPILL RESPONSE KIT APPEARANCE

5.1 Scope of Section

This section provides requirements and recommendations for the appearance of a spill response kit container.

5.2 Mobile Bin Colour Legend

5.2.1 Where mobile bins are used as a spill response kit container, the mobile bin shall have a lime green body.

5.2.2 Different coloured lids shall designate the type of sorbents contained in the spill kit. The required colour coding of mobile bin lids is as follows:

(a) White lid shall be used to designate “OIL AND FUEL ONLY” spill response kit

(b) Yellow lid shall be used to designate “HAZCHEM” spill response kit

(c) Grey lid shall be used to designate “GENERAL PURPOSE” spill response kit

5.2.3 Where weather protection caps are fitted to the spill response kit container, the weather protection cap colour must be the same colour as the container lid.

5.2.4 Clear weather protection caps can be used provided that container lid is clearly visible and the container lid colour is readily identifiable.

5.3 Colour legend for spill response kit containers other than mobile bins

5.3.1 Spill response kit containers that are not mobile bins are exempt from mobile bin colour requirements.

NOTE: Though not mandatory, it is recommended that spill response kit containers other than mobile bins adhere to the same colour designations as the mobile bins.

SECTION 6 SPILL RESPONSE KIT DESCRIPTORS

6.1 When describing spill response kits the following terminology shall be used.

(a) Spill response kits that contain sorbents designed to absorb or adsorb hydrocarbons spills and leaks shall be described as “OIL AND FUEL” or “OIL AND FUEL ONLY”

NOTE1: It is acceptable to replace “FUEL” with “PETROLEUM”

NOTE 2: It is acceptable to replace “AND” with “&”.

NOTE 3: It is the user’s responsibility to determine sorbent suitability

(b) Spill response kits designed to adsorb or absorb spills and leaks of non-aggressive hydrocarbon liquids and aqueous solutions shall be described as “GENERAL PURPOSE”

NOTE: It is the user’s responsibility to determine sorbent suitability

(c) Spill response kits designed to adsorb or absorb spills of hazardous chemicals shall be described as “HAZCHEM”

NOTE 1: It is acceptable to replace the word “HAZCHEM”NOTE: It is the user’s responsibility to determine sorbent suitability

6.2 When referring to the capacity of a spill response kit, the following protocols shall apply;

(a) Where spill response kit contents have undergone sorbency testing as described in Section 2, the primary descriptor and reference to spill response kit capacity shall refer to the maximum quantity of liquid that can be absorbed or adsorbed by the contents of the spill kit.

(b) Secondary references and descriptors may include the volume of the spill response kit container.

SECTION 7 SPILL RESPONSE KIT LABELLING

7.1 This section describes wording and format of primary descriptors to be displayed on a spill response kit.

(a) The following words shall appear on spill response kits that contain sorbents designed to absorb or adsorb hydrocarbons spills and leaks:

OIL & FUEL ONLY SPILL KIT

Or

OIL & FUEL SPILL KIT

NOTE 1: It is acceptable to replace “&” with the word “and”.

NOTE 2: It is acceptable to replace “FUEL” with “PETROLEUM”

NOTE 3: “SPILL RESPONSE KIT” & “SPILL CONTROL KIT” are acceptable variants

(b) The following words shall appear on spill response kits that contain sorbents designed to absorb or adsorb spills and leaks of non-aggressive hydrocarbon liquids and aqueous solutions:

GENERAL PURPOSE SPILL KIT

NOTE: “SPILL RESPONSE KIT” & “SPILL CONTROL KIT” are acceptable variants

(c) The following words shall appear on spill response kits that contain sorbents designed to absorb or adsorb hazardous chemical spills and leaks response kit container hazardous chemicals:

HAZCHEM

NOTE: “SPILL RESPONSE KIT” & “SPILL CONTROL KIT” are acceptable variants

7.2 The maximum sorbent capacity of the spill response kit, as determined by Section 4 of this standard, shall be displayed on the spill response kit container.

7.3 The primary descriptors must appear on the front of the spill response kit container. The primary descriptors may also be displayed on the sides or back of the spill response kit container.

7.4 When displayed on a mobile bin spill response kit container, the minimum font size of primary descriptors set out in section 7.1 and 7.2 is 50mm for capital letters and 25mm for lower case letters. The colour of the text shall contrast with the background colour.

7.5 When displayed on a mobile bin spill response kit container, the maximum font size of secondary descriptors set out in section 6.2(b) shall not exceed 25mm.

7.6 When displayed on other spill response kit containers, the minimum font size of primary descriptors set out in section 7.3 does not apply. All other clauses in Section 7 apply.

NOTE: Though not mandatory, it is recommended that spill response kit containers other than mobile bins adhere to the same font size as the mobile bins

SECTION 8 Mark of Compliance on Spill Response Kits

8.1 Should a spill response kit supplier adhere to all aspects of Section 4, 5, 6 & 7 of this industry standard, an authority shall be issued by AusSpill for the supplier to affix the “AusSpill Mark of Compliance” to the respective spill response kit.

8.2 In order to be compliant with this standard, spill response kits shall display the AusSpill Mark of Compliance.

NOTE: See Appendix A for AusSpill Mark of Compliance

SECTION 9 Maintenance

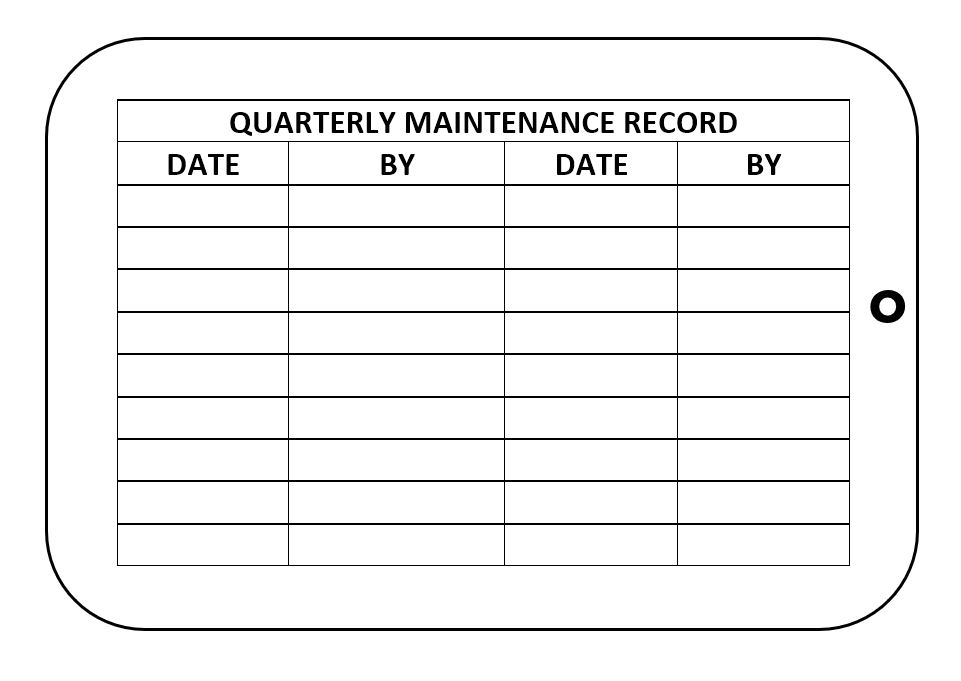

9.1 Each spill response kit shall be inspected and necessary maintenance performed at minimum interval of every 3 months.

9.2 A tag shall be permanently attached to each spill response kit, to be marked at the completion of each inspection.

NOTE: An example compliance tag is shown in Appendix B

9.3 The interval may be varied on the basis of a documented risk assessment.

APPENDIX A

MARK OF COMPLIANCE

(Normative)

ASCS 2695 COMPLIANT

Appendix B

EXAMPLE COMPLIANCE TAG

(Informative)

APPENDIX C

DEPLOYMENT AND SAFETY CONSIDERATION

(Informative)

C1 Personal safety is the main priority when responding to any spill. Each spill kit should contain personal protection equipment (PPE) required to safely respond to the spill. Refer to Section 8 of the SDS of the liquid spilled for personal protection equipment requirements. It is the user’s responsibility to ensure that correct PPE is readily available.

C2 Rapid response to spills is critical in minimising risks to the safety of personnel, property and the environment. A spill response kit should be positioned in a readily accessible location in close proximity to where chemicals are used, decanted, stored or in transit.

NOTE: It is recommended that spill response kits should positioned not more than 15 metres from identified spill risks.

C3 Each spill response kit should be located on the same level as the identified risk and the path of access should be free of obstructions that may interfere with immediate access to equipment.

C4 Each spill kit location should be identified with a highly visible sign complying with AS 1319 positioned so the sign is visible throughout the area served by the unit. The area around the spill response kit shall be well illuminated.

C5 All staff should be trained in how to safely and effectively deploy spill response kits in the event of a spill.

C6 Emergency services should be notified when—

- the spill has spread, or has the potential to spread, beyond the boundary of the installation;

(b) it is beyond the resources of the occupiers to clean up the spill or leak effectively and

safely;

- the protective equipment is inadequate for dealing with the situation;

- staff are not experienced or trained in dealing with the situation; or

(e) staff and the public are, or could potentially be, placed at risk.

APPENDIX D

LIST OF REFERENCE DOCUMENTS

(Normative)

References

BS7959-1 Materials used for the control of liquid spillages, Part 1: Determination of sorbency.

AS1940:2017 Storage and handling of flammable and combustible liquids

AS1319-1994 Safety signs for the occupational environment

AS3780-2008 Storage and handling of corrosive substances

AS NZS 2022-2003 Storage and handling of anhydrous ammonia

AS NZS 3833-2007 The storage and handling of mixed classes of dangerous goods, in packages and intermediate bulk containers

AS NZS 5026-2012 Storage and handling of Class 4 dangerous goods

Work, Health and Safety Regulations 2011